Part II: Design Criteria: Problems And Solutions

3. Miscellaneous High Voltage Design Problems

A. Further Notes on Insulation, Construction

i. Lucite, the HV "Wirehead's" Friend! [7]

Some Properties of Lucite

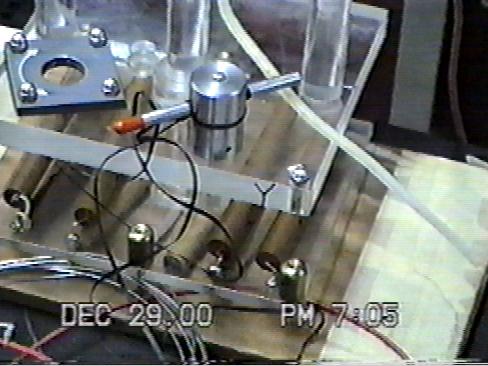

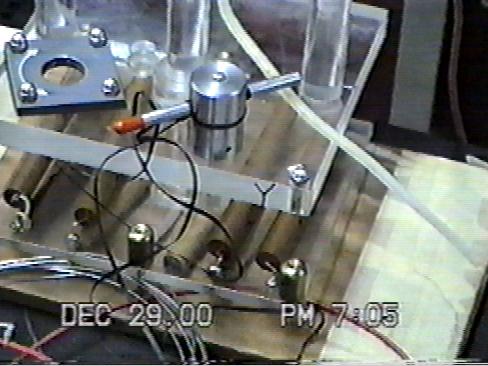

The rectifier bridge from a (factory pre-busted) Sorenson 1061 supply.

This structure, like the rest of the guts of the supply, is mounted on

Lucite. The whole thing is immersed in dielectric mineral oil, rated

for a minimum breakdown voltage of 25kV/mm. Note the smooth, hemispherical

surfaces of the brass contacts. More on that follows.

ii. The "Good Oil".

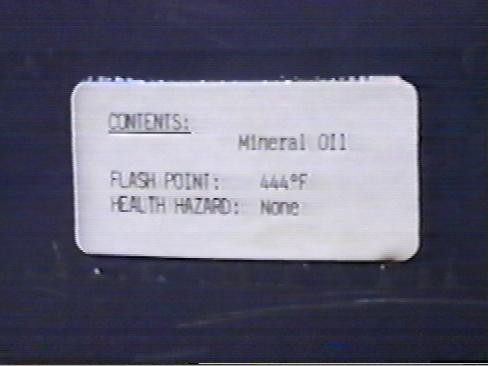

Dr. William S. Bickel's aged, private reserve. I declined his

generous offer, not knowing more about this particular oil.

Dr. William S. Bickel's aged, private reserve. I declined his

generous offer, not knowing more about this particular oil.

Rather than risk a "brand new" (27 yr. old) supply on oil which probably

had gathered moisture and other impurities, it was decided that Tucson

Electric Power would be tapped for some free virgin stuff. Catch-phrases

like "fusion research", "progress" and "starving student" were invoked

and voila! the oil was obtained. The mean breakdown voltage

was tested on the spot at TEP at 47.2 kV/mm, almost twice what Sorenson,

specified. No flashover or even detectable leakage current occurred

while "aging in" the oil. There have been no problems with

the supply since it was started.

Rather than risk a "brand new" (27 yr. old) supply on oil which probably

had gathered moisture and other impurities, it was decided that Tucson

Electric Power would be tapped for some free virgin stuff. Catch-phrases

like "fusion research", "progress" and "starving student" were invoked

and voila! the oil was obtained. The mean breakdown voltage

was tested on the spot at TEP at 47.2 kV/mm, almost twice what Sorenson,

specified. No flashover or even detectable leakage current occurred

while "aging in" the oil. There have been no problems with

the supply since it was started.

iii. Raceways, More on Wiring Insulation

Electro-Nylon Tubing (ENT) Provides supplementary insulation while

supplying a raceway in which a grounding conductor can be run to protect

against RF, shorts and mechanical injury to the conductor.

Electro-Nylon Tubing (ENT) Provides supplementary insulation while

supplying a raceway in which a grounding conductor can be run to protect

against RF, shorts and mechanical injury to the conductor.

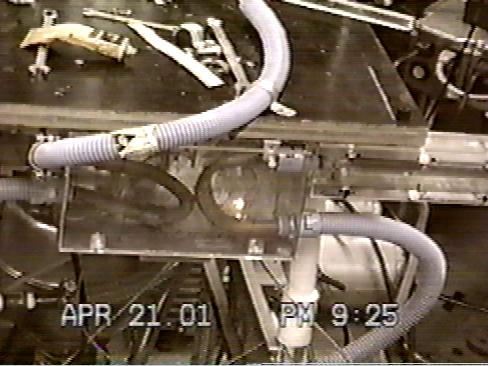

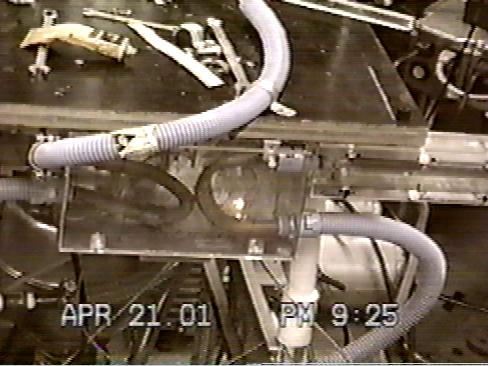

Load resistor(s) housed in Lucite box. Wire junctions to the resistor

are a likely place for arccing. Machine screws made of nylon.

Power leads are connected by HV banana plugs and held in place by threaded

ENT connectors. Wires are further insulated with latex tubing in

metal junction box, since there are splices in there.

Load resistor(s) housed in Lucite box. Wire junctions to the resistor

are a likely place for arccing. Machine screws made of nylon.

Power leads are connected by HV banana plugs and held in place by threaded

ENT connectors. Wires are further insulated with latex tubing in

metal junction box, since there are splices in there.

B. Ion Optics, Sharp Edges, Points, Cracks and Other Sources of

Grief

i. Flux and Charge Distibution Near Sharp Edges

Recall the hemispherical contacts on the rectifier bridge? Mathematicians

abhor discontinuities and so do electrons. Recall that on a conductor

in an E field, charge will be distributed in such a manner

that there will be 0 potential in the conductor. [1] Note how the

flux density increases near the curved edges

nearest the source. The charge density likewise increases.

Now bring these curves to a pointed, sharp edge. The result?

Surface charge density tends to infinity! Arccing occurs. Observe

the glow around the threads of the brass screw at the base of the

system.

ii. Rude Surprises

Now suppose there was a small flaw in some crucial insulation, like

the 1/2" Lucite dowel around the inner conductor in the HV feed.

Suppose that it was only slightly beveled, so that a tiny portion of that

conductor might be exposed. See where the glass HV feed meets the

inner Lucite dowel?

There was a slight bevel (not shown), made with the tip of a drill bit,

which let the tip of the glass nest in the Lucite. Drill bits aren't

ideally suited to precision machining, which was called for. A small

chip was made in the bevel. It was enough to allow a short.

A new dowel was cut and the deep 3/8" bevel which matched the end of the

glass feed precisely was slowly turned on a lathe. High voltage is

extremely

unforgiving!